SPECIAL SYSTEMS

Lean gas treatment RTO

Lean gas treatment plants are used for gas mixtures with a calorific value from approx. 0.5 kW thermal to 3.5 kW

used thermally.

They are used for the safe oxidative disposal of gases that are no longer combustible.

Areas of application

- Landfills at the end of their useful life (replace the gas flare)

- Off-gas utilization in gas processing plants

- Gas utilization in industrial production processes

Execution

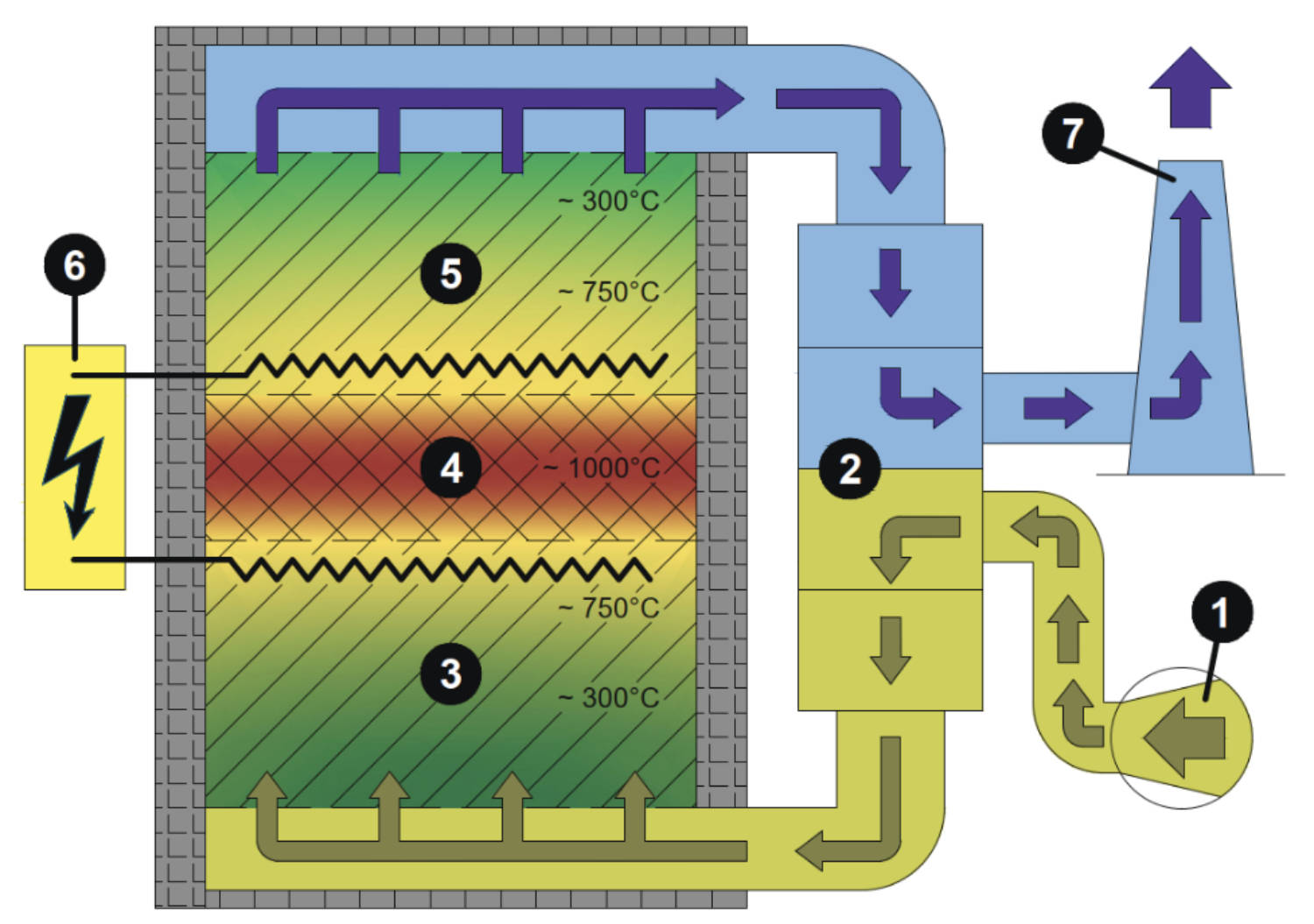

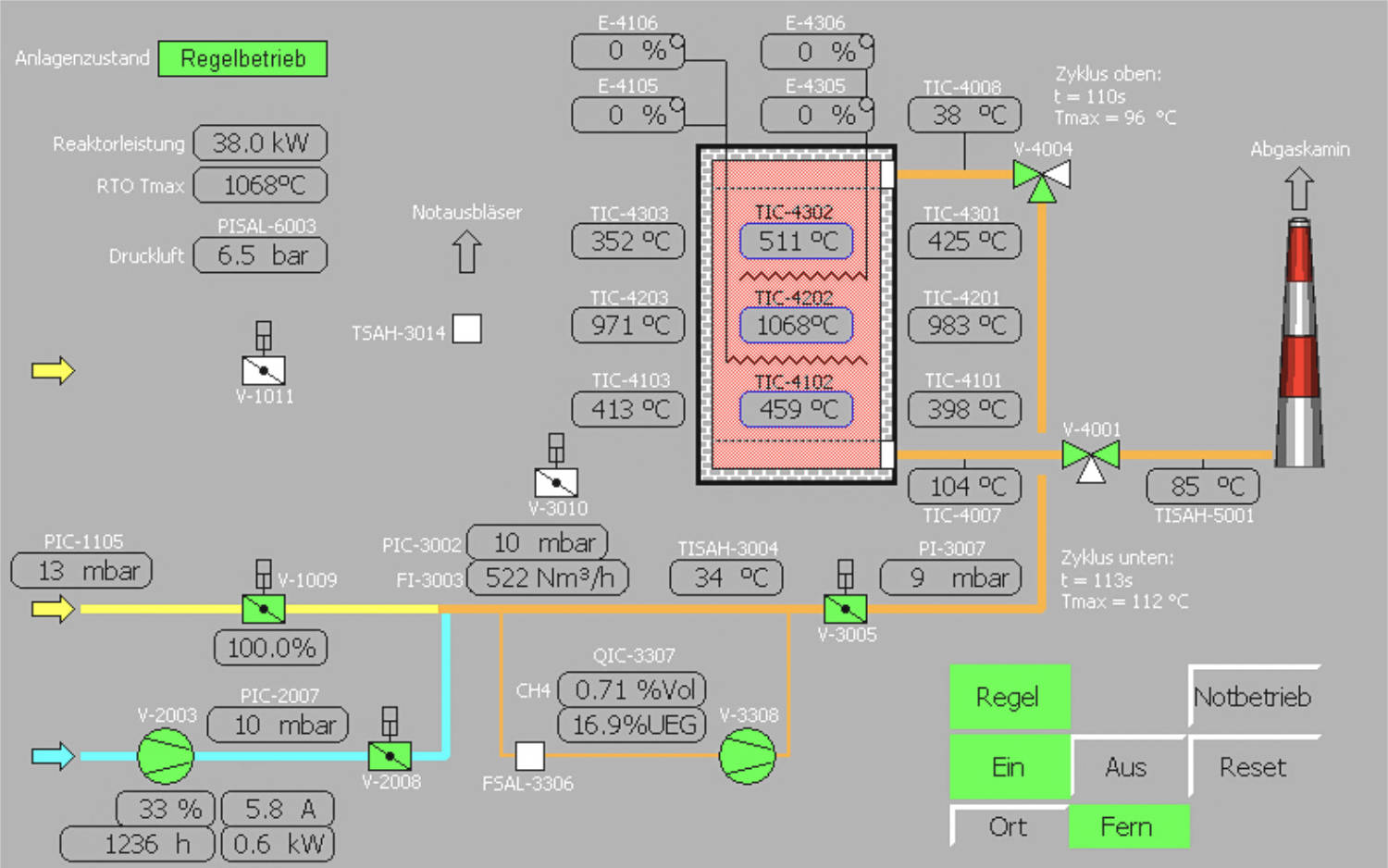

At Gastechnik Himmel RTO type Heos The offgas is diluted with fresh air and passed through a reactor bed

At temperatures above 1000 °C, organic compounds are oxidized flamelessly.

Heating is done electrically, therefore no additional burner system or auxiliary firing is required

necessary and is therefore low in NOx.

The offgas to be treated must have a calorific value of at least 7 kWth in order to

to ensure autothermal operation.

- 1 - Exhaust inlet

- 2 - Switch box

- 3 - Ceramic heat exchanger bed 1

- 4 - Reaction zone

- 5 - Ceramic heat exchanger bed 2

- 6 - Electric heating

- 7 - Exhaust chimney in atmosphere

The temperature in the reactor shifts in the direction of flow, so the flow direction is changed in a switch box depending on the temperature. The reactor thus acts as a recuperative heat exchanger.

The hot exhaust gas cools down again at the reactor outlet and is discharged via the exhaust stack.